In the bustling environment of warehouse operations, maintaining safety and efficiency is paramount. A well-organized warehouse not only boosts productivity but also ensures the safety of workers. One critical yet often overlooked aspect of this organization is line striping. Line striping plays a crucial role in creating a well-structured and safe workspace, helping to prevent accidents and streamline workflow.

The Importance of Safety in Warehouse Operations

Warehouse operations come with inherent risks. According to the U.S. Bureau of Labor Statistics, there were 4.8 injuries per 100 full-time workers in the warehousing and storage industry in 2020. These injuries can lead to significant downtime, increased costs, and harm to workers.

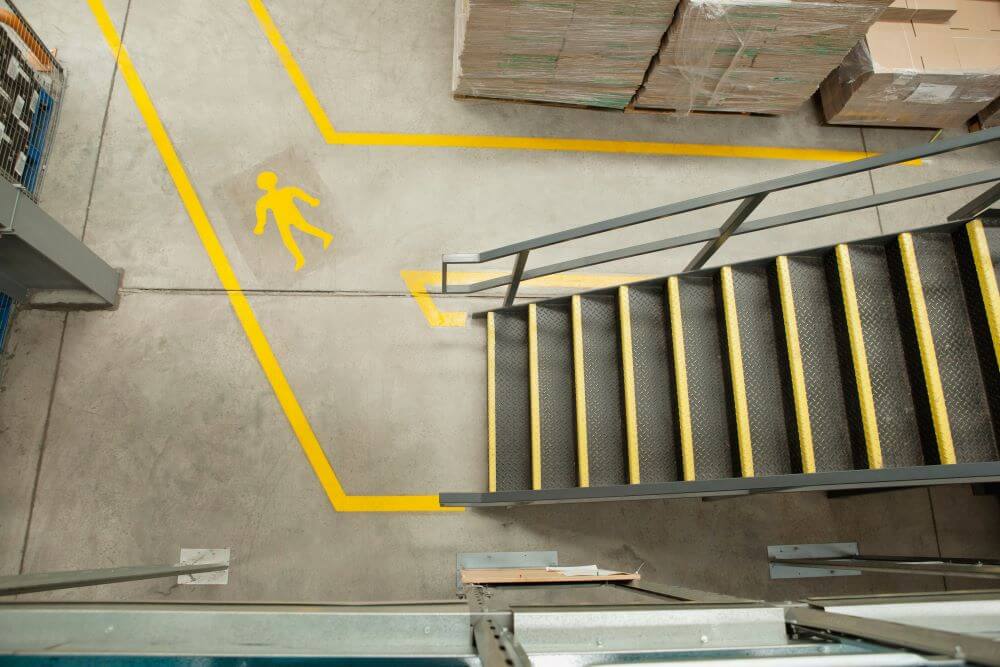

Accidents in warehouses can have a profound impact on productivity and operational costs. Injuries lead to downtime, medical expenses, and potential legal liabilities, all of which can disrupt the smooth functioning of warehouse activities. Clear and visible line striping helps mitigate these risks by providing visual cues that guide workers, thereby reducing the likelihood of accidents. Properly marked pathways, storage areas, and hazardous zones help in navigating the warehouse safely, preventing collisions and trips.

Enhancing Efficiency with Line Striping

Efficiency in warehouse operations is closely linked to organization. Line striping helps in organizing the workspace, creating a more streamlined workflow. Clearly marked areas for different activities ensure that workers can quickly and easily find what they need, reducing wasted time and effort.

For instance, designated pathways for pedestrian and vehicle traffic prevent congestion and streamline movement within the warehouse. Clearly defined storage zones ensure that items are stored in the correct locations, making it easier to locate and retrieve them. This level of organization not only enhances efficiency but also contributes to increased productivity by minimizing delays and optimizing workflow.

Types of Line Striping

There are several types of line striping materials available, each with its own set of advantages and disadvantages. The choice of material depends on factors such as the warehouse environment, budget, and specific needs.

- Paint: Traditional paint is a cost-effective option for line striping. It can be applied quickly and easily, making it suitable for large areas. However, paint may wear off over time, especially in high-traffic areas, requiring regular maintenance and reapplication.

- Tape: Floor marking tape is another popular choice for line striping. It is easy to apply and remove, making it ideal for temporary or frequently changing layouts. Tape is also available in a variety of colors and patterns, allowing for customization. However, it may not adhere well to certain surfaces and can peel off over time.

- Thermoplastic: Thermoplastic line striping is a durable and long-lasting option. It is applied using heat, creating a strong bond with the floor surface. Thermoplastic is resistant to wear and tear, making it suitable for high-traffic areas. However, it is more expensive and requires specialized equipment for application.

When choosing the right type of line striping for a warehouse, it is essential to consider factors such as the level of traffic, the type of flooring, and the desired longevity of the markings.

Implementing Line Striping: Best Practices

Successful line striping implementation requires careful planning and execution. Here are some best practices to consider:

- Planning and Preparation: Conduct a thorough assessment of the warehouse layout and identify areas that require line striping. Create a detailed plan, including the types of markings needed, their locations, and the materials to be used. Ensure that the floor surface is clean, dry, and free of debris before applying line striping materials.

- Application Process: Use high-quality materials and equipment to ensure durability and visibility. Follow manufacturer instructions for the application of paint, tape, or thermoplastic. Allow sufficient drying or curing time before allowing traffic on newly striped areas.

- Maintenance Tips: Regularly inspect line striping to ensure it remains visible and intact. Address any damage or wear promptly to maintain safety and efficiency. Consider periodic re-striping to keep markings clear and effective.

Additional Resources

For those interested in further enhancing their warehouse operations through line striping, here are some valuable resources:

- OSHA Guidelines: The Occupational Safety and Health Administration (OSHA) provides guidelines and standards for workplace safety, including recommendations for line striping in industrial environments. OSHA Guidelines on Warehouse Safety.

- Professional Line Striping Services: Hiring a professional line striping service can ensure high-quality and long-lasting results. Companies like We Do Lines offer specialized services for warehouse environments. We Do Lines: Regional Parking Lot Striping & Maintenance

- Warehouse Safety and Efficiency Best Practices: The Warehousing Education and Research Council (WERC) offers resources and educational materials on improving safety and efficiency in warehouse operations. WERC Resources.

By utilizing these resources and implementing effective line striping practices, warehouse managers can create a safer, more efficient, and ultimately more successful operational environment.

Line striping is a powerful tool that can significantly enhance the safety and efficiency of warehouse operations. By providing clear visual guidance, line striping helps prevent accidents, streamline workflows, and create an organized and productive environment. Whether using paint, tape, or thermoplastic, it is essential to follow best practices for planning, application, and maintenance to ensure the effectiveness of line striping.

As warehouse managers, investing in high-quality line striping solutions is a proactive step toward creating a safer and more efficient workplace. By staying informed about technological advancements and continuously assessing and improving line striping systems, warehouses can maximize their operational potential and achieve long-term success.