Safety is a paramount concern in warehouse operations, where the dynamic environment is full of potential hazards related to vehicle traffic, equipment handling, and the storage of goods. In this setting, floor striping plays a critical role in managing risks and enhancing overall safety. This article explores the essential practices for effective floor striping in warehouses, offering guidance on how to maintain a safe and efficient workspace.

Importance of Safety in Warehouse Operations

Warehouses are central hubs for product distribution and storage, and their efficiency directly impacts the broader supply chain. However, the combination of manual labor, machinery, and frequent movement creates an inherently risky environment. Safety measures are not only regulatory requirements but also critical to prevent costly accidents and injuries. A safe warehouse is more productive and experiences fewer disruptions, which in turn, supports a healthier bottom line and a stronger reputation for reliability and responsibility.

Role of Floor Striping in Enhancing Workplace Safety

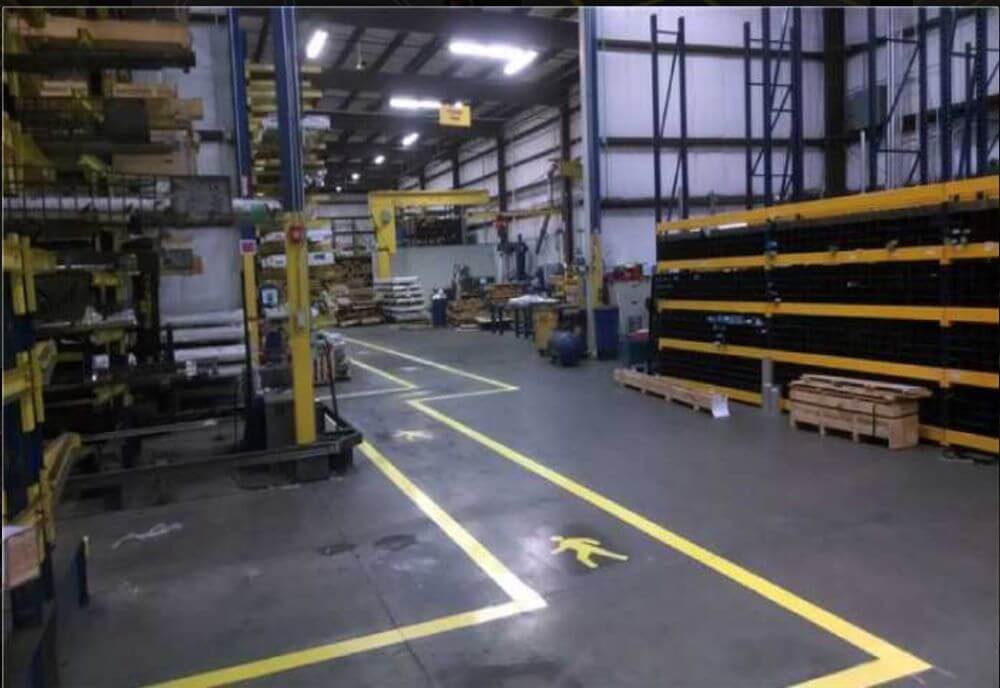

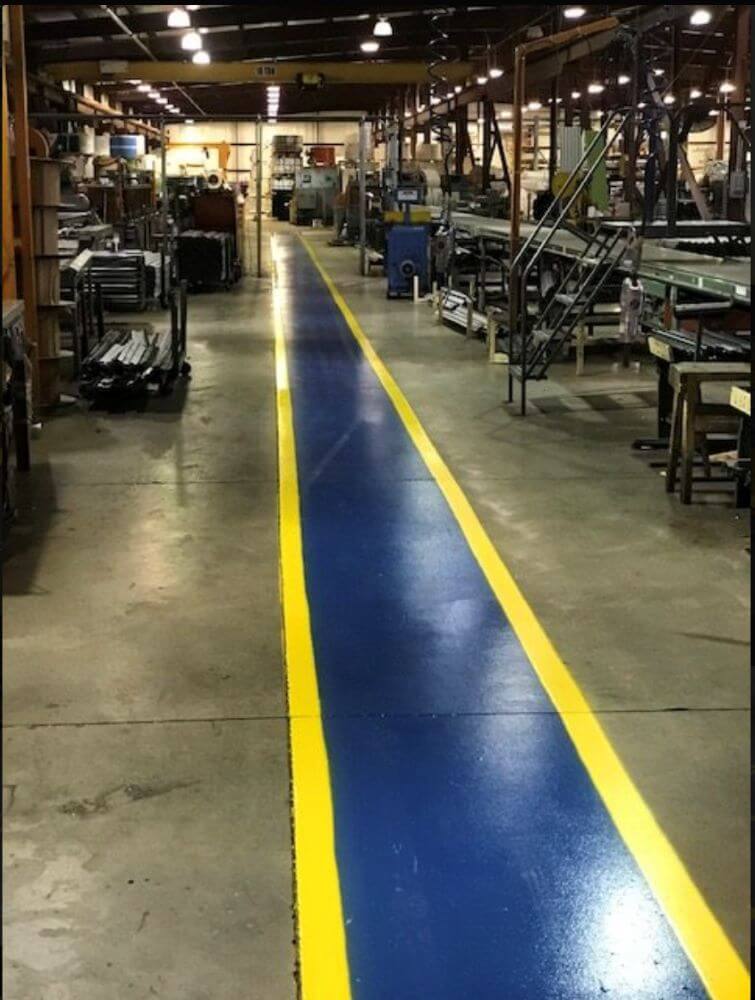

Floor striping serves as a low-cost yet effective method to significantly improve safety in warehouses. By clearly delineating walkways, vehicle pathways, and hazardous areas, floor striping prevents accidents by guiding traffic and promoting orderly movement and storage. It acts as an essential visual cue that can be universally understood by all warehouse personnel, regardless of language barriers, which is especially useful in diverse workforces.

Understanding Warehouse Floor Striping

Definition and Key Functions of Floor Striping

Floor striping involves applying lines of paint or adhesive tape to the warehouse floor to outline different zones and paths. These markings are strategically placed to control the flow of traffic, enhance visibility, designate storage areas, and point out safe walking paths for workers, among other functions.

Benefits of Floor Striping for Safety and Navigation

The advantages of implementing floor striping include:

- Improved Safety: Clearly marked paths reduce the risk of forklift accidents, help manage pedestrian and vehicular traffic, and highlight emergency egress routes.

- Enhanced Navigation: New employees or external visitors can easily navigate through the facility without extensive guidance, reducing the potential for errors and accidents.

- Increased Efficiency: Organized traffic flow and designated areas for various activities streamline operations, reduce time spent on locating items, and decrease the chances of logistical errors.

- Regulatory Compliance: Many safety standards require specific markings in workplace environments. Effective floor striping ensures compliance with these regulations, helping avoid legal repercussions and fines.

Best Practices for Planning Floor Striping

Evaluating the Warehouse Layout and Traffic Patterns

Before applying floor striping, it is crucial to understand the unique layout and traffic flow of the warehouse. This evaluation should consider:

- High Traffic Areas: Areas that see a high volume of movement, either pedestrian or vehicular, should have clear and durable striping.

- Interaction Points: Locations where pedestrians and vehicles intersect are particularly risky and need explicit demarcation.

- Environmental Conditions: Areas prone to wetness or spillages may require anti-slip tape or durable paint to withstand these conditions.

Choosing the Right Striping Materials (Paint vs. Tape)

The choice between paint and tape will depend on several factors including budget, expected traffic levels, and permanence of the layout:

- Paint: Offers a permanent solution and can withstand heavy traffic, but requires more time to apply and dry. Ideal for long-term layouts with stable operations.

- Tape: Easier to apply and replace, making it suitable for facilities that frequently change layouts or have lower traffic. It’s less durable than paint but provides flexibility and immediate usability.

Design Considerations

- Color Coding for Different Areas: Standard color codes can help workers quickly recognize different zones. For example, yellow often signifies caution and is used for general markings, while red might indicate hazardous areas or equipment.

- Significance of Stripe Widths and Patterns: Wider stripes are more visible from a distance and are beneficial in high-traffic areas. Patterns like chevrons or dots can be used to indicate directional flows or to alert to changes in floor elevation or other hazards.

Implementation Techniques

Preparing the Floor Surface

Before applying any stripes, the floor must be adequately prepared to ensure the markings adhere properly and last as long as possible.

- Cleaning and Repairing the Surface: The first step is to thoroughly clean the floor to remove dirt, debris, and grease. Any cracks or uneven surfaces should be repaired to create a smooth base, which not only aids in the adherence of the striping materials but also enhances the overall safety of the floor.

- Ensuring Surface is Dry and Smooth for Application: After cleaning, it’s crucial to ensure the floor is completely dry. Any moisture can interfere with the adhesion of paint or tape, leading to premature wear and requiring frequent touch-ups.

Applying the Striping

The actual application of stripes must be executed with precision and planning to ensure maximum effectiveness and durability.

- Techniques for Straight Line Application: Using tools like laser lines or chalk lines can help maintain straight, consistent lines. This precision is vital for ensuring clear, navigable paths that are intuitively followed by warehouse personnel.

- Tips for Ensuring Long-Lasting Adherence: For paint, consider applying a primer first, particularly in high-traffic areas, to enhance the grip of the paint. For tape, applying pressure with a weighted roller can help secure it firmly to the surface.

Maintenance and Upkeep

Regular maintenance is essential to preserve the visibility and functionality of floor striping.

- Regular Inspection Schedules for Wear and Tear: Establish routine inspections to assess the condition of the striping. High-traffic areas may require more frequent reviews and maintenance.

- Methods for Cleaning and Maintaining Visibility: Keep the striped areas clean of dust, dirt, and spills. Use gentle cleaning products that do not erode the striping material.

- When and How to Update or Redo Striping: If striping begins to peel or fade, it should be replaced promptly. Always remove the old markings completely before applying new ones to ensure the best adherence and visibility.

Effective floor striping is crucial for maintaining a safe warehouse environment. It aids in navigation, demarcates safety zones, directs traffic, and significantly reduces the likelihood of accidents. Continuously maintaining and updating floor striping is not just about compliance or aesthetics—it’s a critical component of workplace safety that protects employees, enhances efficiency, and supports the overall operational goals of the organization. Ensuring that these markings are visible and adhered to can fundamentally transform a warehouse from a chaotic and hazardous space into a well-organized and safe environment.